If you are considering an Industrial Dye Sublimation Printer, the first step is to get a basic understanding of the process. There are many benefits of using this type of printer, and knowing these benefits will make your job easier. If you are considering dye-sublimation as a method of printing, here are some reasons why you should consider this type of printing. These benefits will make your job easier and more profitable.

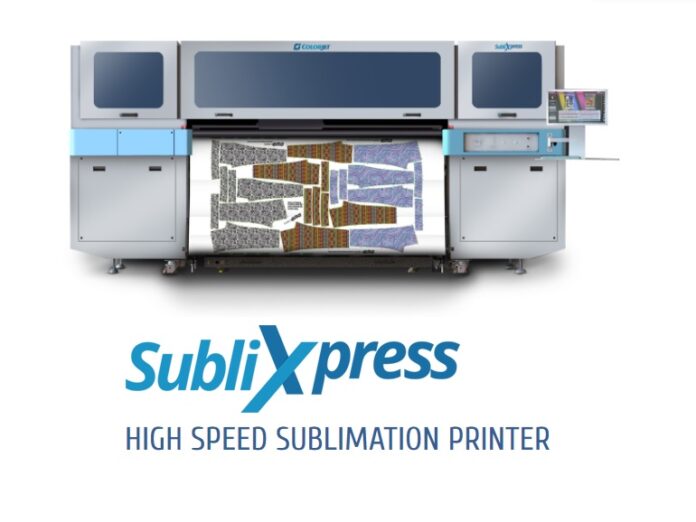

Industrial dye-sublimation printers can be used to print large-scale designs on a variety of materials. They can be as wide as 10 feet. Some models are designed for single-use printing, while others are intended for high-volume production. If you are planning to print on a solid object, such as a t-shirt, a flatbed machine will be more suitable. On the other hand, a caleender printer uses oil-heated drums for heat transfer. It is also best for high-volume printing.

The size of a Dye-sublimation printer will depend on the type of product you need to print on. The 190 Series uses variable-drop greyscale heads from Kyocera. These heads are very effective for producing fine detail and superior image quality. These machines are ideal for businesses looking to produce large quantities of promotional products and apparel. You can choose from a wide range of colors and print speeds.

An Industrial Dye Sublimation Printer allows you to print on non-fabric items. You can purchase these products in bulk and at a discounted price. The advantages of using a dye-sublimation printer include a reduced cost and lower minimum orders. With this machine, you can do large and small-scale printing. And if you want to expand your business, a Dye-sublimation printer can be an excellent choice.

These printers are capable of producing large volumes of high-quality graphics on various surfaces. The 190 Series features a super-fast Kyocera head that prints on light-colored fabrics. With a Karta 190, you can choose from a wide range of different material options. The cost of entry is a major consideration for your business. For example, the ATPColor 190 Series is designed with one-pass printing.

While Dye-sub technology is widely used in the textile industry, it has a huge number of applications. From soft signage to clothing to furniture to sports equipment, the process is a versatile and affordable option. Its advantages make it an ideal solution for companies in the fashion and sports industries. You don’t need a dedicated printer for each item you want to print. You can also invest in a dedicated heat press and reduce your costs.

A single-pass Dye-Sublimation Printer has multiple benefits. The most common is the ability to perform high-volume printing on a wide variety of materials. Inkjet printing is very efficient, as it can make small-scale products look high-quality. In addition to these advantages, industrial Dye-Sublimation Printers are easy to maintain and have low maintenance requirements. In addition, they have many features that can help you to create custom-made products.

An Industrial Dye-Sublimation Printer uses a disperse dye to transfer to a textile. The color gamut of disperse dyes is wide, so they can be used to create high-quality printed products. In addition to the benefits for your business, an Industrial Dye-Sublimation Printer is ideal for small businesses. They allow you to print on textiles of any size, making them the most versatile type of industrial printing available.

While industrial Dye-Sublimation Printers are not cheap, they are extremely effective and flexible. Because they are versatile and can print on a wide variety of substrates, they are a great option for a wide variety of applications. If you need to print on a large scale, an Industrial Dye-Sublimation Printer can produce high-quality results. So, whether you need a product for home use or mass-production, you can count on an Industrial Dye-Sublimation Printer.

When choosing an Industrial Dye Sublimation Printer, it is important to understand that the process is different from eco-solvent and solvent-based printing. For instance, the heat from a heat press may dry the ink in the print head and result in a blotchy print. In order to get the best results from your industrial Dye-Sublimation Printer, be sure to make sure you have enough space for your printer.