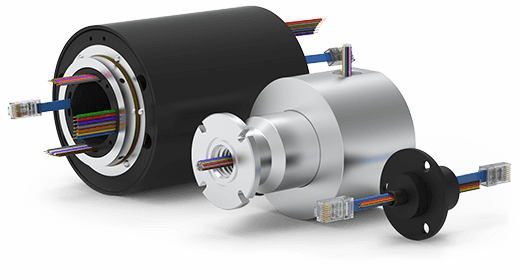

When most people think about wind turbines, large-components come to mind. Small components may make or destroy a system. The pitch control system’s slip ring assembly is also known as an electrical rotary union. When compared to the entire wind turbine, the slip ring is insignificant. Its significance, however, can get overlooked. The turbine will shut down if your slip ring fails or has significant faults.

Even though the slip ring is small, it is significant. That’s why it’s critical to select a slip ring that’s compatible with your turbine’s design. By ensuring that undesired design aspects not get included while crucial design features are, a high-quality, custom-engineered slip ring for wind applications may save money and increase performance. A bespoke design is also less expensive to maintain, has less downtime, and is more productive.

Manufacturers evaluate several aspects when determining the efficacy of a wind turbine slip ring. Maintenance frequency, maintenance downtime, and power transmission are all essential considerations.

The frequency of maintenance

You might believe that a longer life needs more upkeep. The reverse is true if you buy a high-quality slip ring. A slip ring should get built to endure the life of a wind turbine, which is 20 years. It should also be able to withstand 100-200 million rotations before needing to be replaced.

Slip Rings may be easy to maintain. The more information available about the specific turbine circumstances, the better the slip ring can get constructed to last for 20 years. A good slip ring will save you both time and money on components and labor.

Downtime due to maintenance

Quality wind turbine slip rings make it easier to get your turbine up and run again. With good slip rings, you should only have to replace one brush rather than the complete assembly. You’ll spend time replacing functioning brushes and money on extra materials if you use lower-quality slip rings. In addition, excellent slip rings should only take five minutes of annual maintenance.

Transfer of energy

Slip rings used to have a poor record for wasting power and having limited capacity. It is no longer the case. Quality wind turbine slip rings are now incredibly efficient, allowing them to transfer more watts with less power loss. The power factor of the slip ring should be more than 99 percent. The slip ring will impede the electrical system without a near-perfect power factor, and the power loss will get converted to heat, which will harm the slip ring system. Power transmission capacity and power loss are affected by various parameters, including contact size and design. Slip rings that are custom-designed for a particular wind turbine application can assist assure optimal capability and operation.

A necessary component

Every component, just like any other electrical system, has its significance. For the larger-system to function, all of these components must work in tandem. Despite the fact that slip rings are a tiny component of a wind turbine, they are critical to its uptime, efficiency, and profitability. Small slip rings are a huge issue in the grand scheme of things.