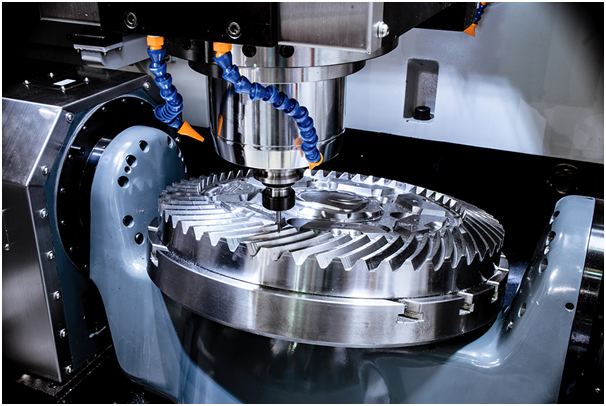

CNC Milling machines are not only used in the mechanical field, but are also widely applied in many different industries such as: Electronics, automobile manufacturing, motorcycles, footwear, apparel… Especially, CNC milling techniques has high automation ability, solves economic problems and brings many benefits to businesses.

What is a CNC Machine?

CNC Milling is the technique of cutting and drilling metal or wood materials using multiple milling blades. Traditional milling machines usually operate by hand, the worker will decide the quality and speed of milling. However, with CNC milling machines, the device is integrated with an intelligent controller, capable of operating automatically according to the settings available on the computer.

What are the advantages of CNC Machines?

- Can cut a variety of solid materials such as: Aluminum, steel, copper, zinc, nylon, PVC, plywood, wood, stone…

- CNC milling technology has fast machining speed, shortens production time, increases output and productivity, and ensures high accuracy and uniformity for all products.

- The milling cutter has many cutting edges, long service life, large feed volume.

- If the workpiece is broken, ensuring the safety of workers during construction.

- Can process material surfaces in many different shapes: plane, cylindrical face, keyway, keyway, complex surface, round face, thread cutting, gear milling…

- CNC milling machines can solve 20% of the work of the material cutting process.

What is the importance of CNC milling method?

Even a small CNC machine is capable of solving problems that other metalworking methods cannot. Specifically, without the use of CNC milling machines, the cutting of metal machine parts used when assembling cars and aerospace will have a higher probability of encountering risks and errors, thereby leading to many other serious consequences.

In addition, with the support from the CNC controller operating automatically through the computer, people can install design files according to their needs. The milling machine will operate and deliver high-precision processed products, businesses will save on prototyping costs.

Not only used in industrial and mechanical fields, CNC milling machines also have applications in many other fields to produce familiar items such as: Interior and exterior decoration, aluminum processing, sculpture, advertising, prototyping, detailed engraving and decorative wood patterns…

Currently, most businesses and factories process products according to customer requirements. This requires businesses to regularly update and constantly improve the production process. With a CNC plasma cutting machine, just changing the settings on the computer will solve this problem simply.

Popular types of CNC milling machines on the market

To make it easier to choose, you need to find out what type of milling machine is commonly used in the market. 3 types of milling machines that are favored by many businesses are: Vertical milling machines, horizontal milling machines and knee milling machines.

- Vertical milling machine: This is a 3-axis milling machine, the main axis of the milling machine will be installed perpendicular to the table. In a vertical CNC milling machine, the spindle will be fixed, the table moves along the x and y axes.

- Horizontal milling machine: The main axis of the milling machine is placed parallel to the table. In operation, although less flexible than vertical milling machines, horizontal milling machines are especially suitable for long and thick material surfaces.

Knee milling machine: This type of milling machine has a table that moves up and down flexibly and the knee part can be easily adjusted.